ABC Analysis – How to optimize warehouses and inventory

ABC Analysis is a simple way to classify items (products, files, folders or anything) used when we want to optimize the layout of our inventory or warehouse. This methodology is generally used in logistic companies and stores to classify any kind of stock. Its purpose is to organize the stock products to reduce the time that the workers are going to need to manage this stuff (the time to keep, search, obtain or move items in the warehouse or shelves).

How to do an ABC Analysis?

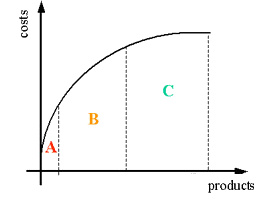

To organize our stock according to the rules of the ABC Analysis, firstly we have to identify the most important items that we have in our catalogue. Therefore, we are going to classify our items in 3 groups:

– Group A: Here we put the most important item (the most used, the best sellers or the most urgent to obtain in case of necessity). In a store, these items are usually the ones which give to the company the most amounts of profits.

– Group B: These are items less used, or which have a secondary importance.

– Group C: These are those items which are nearly irrelevant. Many times to have them in the store costs more money than the profit they bring.

Once the classification have been done, we have to place the Group A items in the most accessible zone of the Warehouse (eg. in the warehouse entrance, in the front of the shelves, in the more visited areas of the stores). Then, the Group B items have to be placed and finally, Group C items will be placed in the remaining space, because the need to dispose of them is less urgent.

The ABC method is used to increase the efficiency of the stores and to save time for managers when they have to pick up and leave items.

Original post: http://www.pdcahome.com/analisis-abc/

This article is very interesting and useful. I like it a lot.