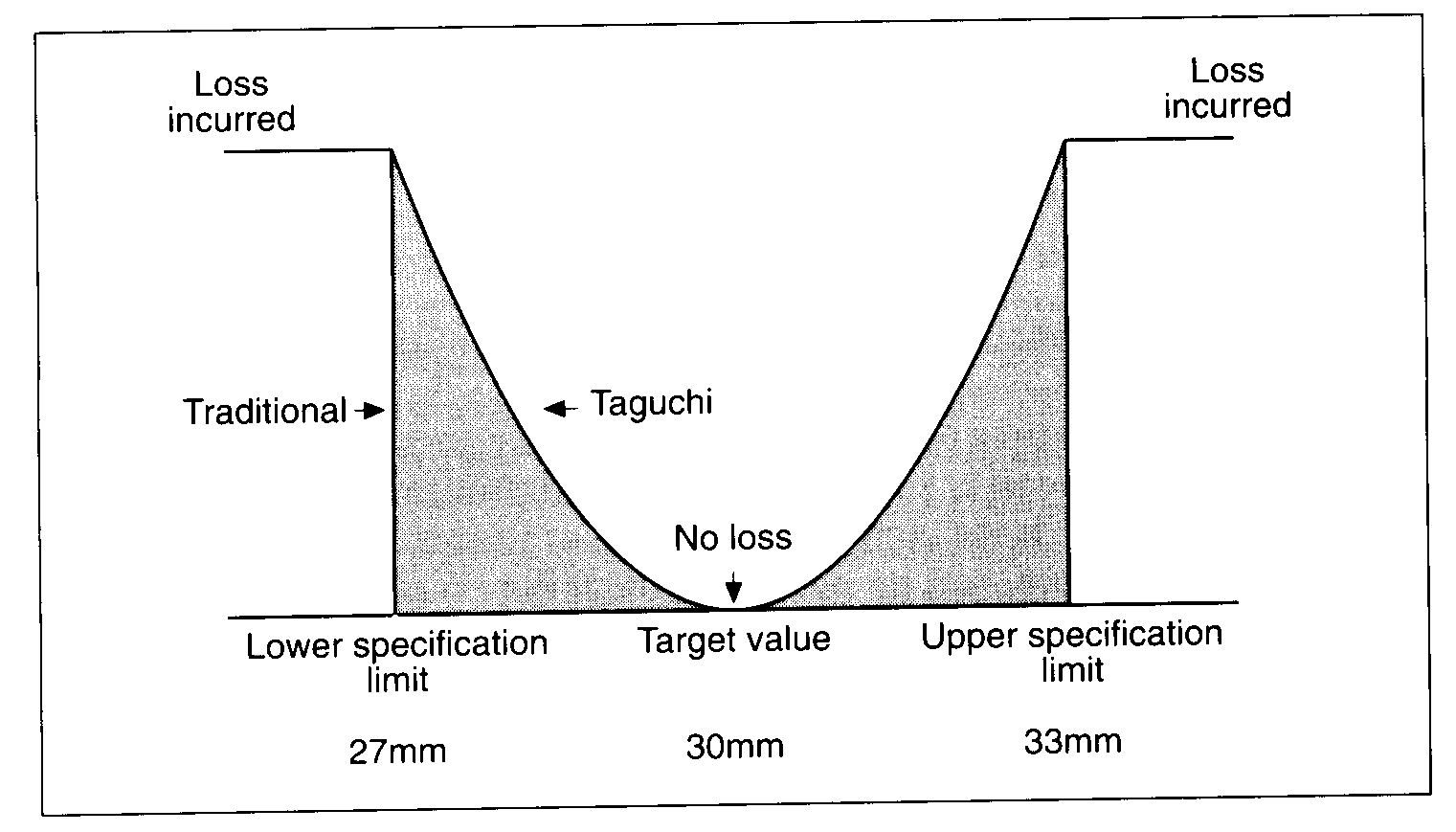

Quality loss function (Taguchi): How to control the lack of quality in a product

The role of quality loss function, commonly called Taguchi loss function (by its creator Genichi Taguchi, in the second half of the twentieth century), is a calculation tool used in engineering and quality control. This tool is used to evaluate the “quality loss” on a project, product or service with respect to its optimal quality level.

The main goal of Taguchi’s methodologies are that they are focused on designing and manufacturing products in few time with high quality, avoiding having to use the common “try and fail” method, which is more expensive and slower.

To achieve these improvements, we will have to optimize the product design and the manufacturing processes using engineering quality and statistics.

The loss function of Taguchi quality

The loss function gives us a way to calculate the “quality loss” which suffers an analyzed characteristic of our product with respect to the quality goal (the target) that we want to obtain.

The loss function is like this:

L = K * (Y – M) ^ 2

L is the result value of the function, generally measured in monetary units.

Y is the target, or ideal value of the analyzed characteristic.

M is the mean of the obtained values of the analyzed characteristic in the real production.

K is a constant that is responsible for converting (Y – M) ^ 2 into monetary units.

Therefore, if for our analyzed characteristic in the product, the value L is zero, this means that the value obtained is our target. If L is greater than zero, then it means that we are moving away from the target.

For example, if the analyzed characteristic (production time, delivery time, cost …) has to be Y = 30unids., but in practice we are measuring that on average it is M = 35unids., and this deviation cost K = 5 $/unit. ^ 2, then the result is L = 5 * (35-30) ^ 2 => L = 125 €. It should be noted that the value of L is always greater than or equal to zero, and Y-M grow quadratically, so K must be expressed in the correct units.

How to use the loss function in quality control

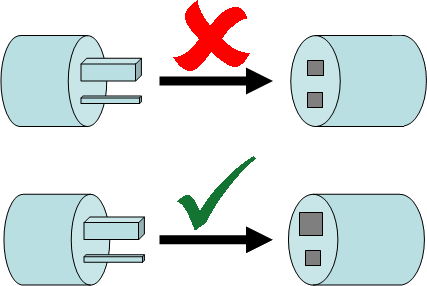

During the designing and manufacturing of a product all the parameters and the manufacturing process have to be properly controlled. A deviation in some parameters can produce lack of quality, so we have to control them to be in a range where the product is inside the specifications. To have success in this task, is important to define what are the key characteristics, which can produce more lost of quality in the final product, and therefore, they have to be more controlled.

Once identified the key parameters, we proceed to determine their current status, (to analyze if L = K * (Y – M) 2 is zero or is a high value), and later we have to study what are the causes of the quality lack to solve the problems. The next step is to make an interpretation of the results, thus we can make an overall assessment of the quality losses in economic units and implement solutions to minimize these losses as much as possible.

Original post (in Spanish): http://www.pdcahome.com/funcion-de-perdida-taguchi