POKA YOKE – A method to create a Safe Design

What is Poka Yoke?

Poka-Yoke is a methodology created in Japan which means “fool-proof”. Its purpose is to prevent or avoid mistakes that can be caused by humans or by machines during their activities. Poka Yoke can be also implemented to facilitate errors detection.

If we focus in manufacturing operations, which can be assemblies or other simple but repetitive activities, the risk of error can be very high regardless the complexity of the tasks. PokaYoke System helps to minimize that risk with simple measures like create an easier design or paint the different pieces to make the activities easier.

Poka-Yoke can be designed to handle errors (control function) or to warn them (warning function):

1 – Control function:

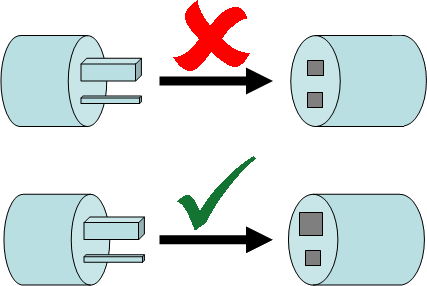

In this case, Poka-Yoke is designed to prevent potential mistakes. To do this, it uses different shapes or colours to differentiate the correct assembling of each piece of our product.

2 – Warning function:

In this case, we assume that an error could happen. We have to design a system which reacts when an error happens, therefore it would warn the operator about the failure. For example, you can use light or pressure sensors, alarms, etc.

How to implement a Pokayoke system:

Some types of design methods can be…

– A design that permits plug the pieces only in the correct way: If you try to fit the pieces in a wrong way, it won’t fit.

– Color codes: For example in the computers jacks/plugs, each jack has a different colour.

– Arrows and other indications such as “A-> <-A” to indicate where each piece have to be fitted and what is its orientation.

The advantages of using a Poka Yoke system are the followings:

– It minimizes or avoids the risk of errors and nonconformities.

– The operator can focus on the operations that add more value, rather than wasting his time to prevent errors, to check or to correct them.

– Implement a Poka-Yoke system means improving the quality acting on the errors source, rather than on doing quality controls after finishing the product, which are more expensive and inefficient.

– It’s easy to implement and cheap.

Poka-Yoke’s mission is to support the workers during their activities. In the case when the device is part of the operation of a machine, we will be talking about another similar concept: “jidoka”.

Original post (in Spanish): http://www.pdcahome.com/poka-yoke